Isku-dhafka Cunnada Matoorka Matoorka Tooska ah

Soo dir weydiin

Isku-dhafka Cunnada Matoorka Matoorka Tooska ah

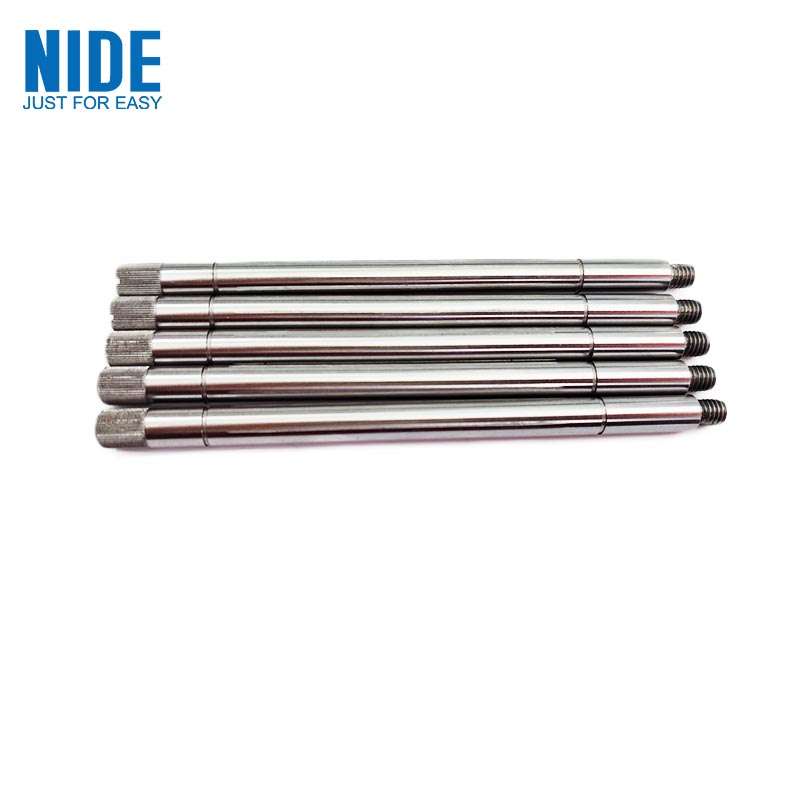

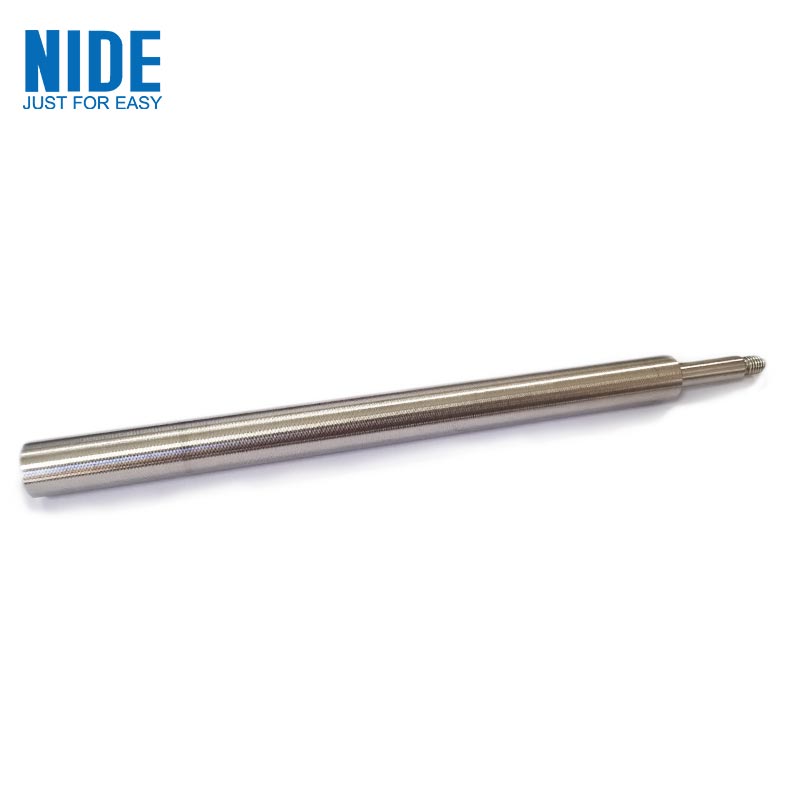

Matooradayada mootooyinka waxay leeyihiin sifooyinka xoogga sare, shuruudaha saxda ah ee saxda ah, caabbinta xirashada wanaagsan, caabbinta daxalka wanaagsan iyo waxqabadka waxqabadka wanaagsan si loo hubiyo waxqabadka iyo nolosha adeegga matoorka.

Soo-saarka mashiinka mashiinka isku-dhafka ah wuxuu u baahan yahay inuu si adag u xakameeyo shuruudaha alaabta, tignoolajiyada farsamaynta iyo tayada si loo hubiyo in tayada iyo waxqabadka shafka ay buuxiyaan shuruudaha isticmaalka. Guud ahaan tixgeli dhinacyada soo socda:

1. Xulashada agabka: Matoorka mashiinka waxaa badanaa laga sameeyaa bir bir ah oo aad u sarreeya ama bir aan lahayn. Doorashada maadada ayaa loo baahan yahay in lagu go'aamiyo iyada oo loo eegayo arrimo ay ka mid yihiin deegaanka lagu isticmaalo qasaha, culeyska, iyo xajmiga usheeda dhexe.

2. Farsamada farsamaynta shaft: Farsamada farsamaynta ee usheeda dhexe sida caadiga ah waxa ka mid ah xidhiidho badan sida leexinta, shiidi, iyo qodista. Xidhiidhiyayaashani waxay u baahan yihiin inay si adag u xakameeyaan saxnaanta mashiinka si loo hubiyo in dhexroorka, dhererka, wareega iyo cabbirada kale ee shafka ay buuxiyaan shuruudaha.

3. Daaweynta dusha sare: Si loo hagaajiyo tayada dusha sare iyo nolosha adeegga mashiinka mashiinka, daaweynta dusha sare ayaa guud ahaan loo baahan yahay. Tusaale ahaan, ciid-qarxinta, polishing, electroplating iyo habab kale ayaa loo isticmaali karaa in lagu daweeyo dusha sare ee shafka.

4. Isku-xidhka iyo kormeerka: Ka dib marka la dhammeeyo soo saarista shafka, ururinta iyo kormeerka ayaa sidoo kale loo baahan yahay. Marka la isku soo ururiyo, fiiro gaar ah waa in la bixiyaa meelaynta iyo ku habboonaanta shafka si loo hubiyo in shafka si sax ah loogu rakibo qasaha. Inta lagu jiro kormeerka, waxaa lagama maarmaan ah in la sameeyo kormeero ku saabsan cabbirka, adkaanta, iyo axial runout si loo hubiyo in tayada shafka ay buuxiso shuruudaha.

Qiyaasta Alaabta (Qeexidda)

|

Bir daxal laheyn |

C |

St |

Mn |

P |

S |

Gudaha |

Cr |

Mo |

Cu |

|

SUS303 |

≤0.15 |

≤1 |

≤2 |

≤0.2 |

≥0.15 |

8 ~ 10 |

17-19 |

≤0.6 |

|

|

SUS303CU |

≤0.08 |

≤1 |

≤2.5 |

≤0.15 |

≥0.1 |

6 ~ 10 |

17-19 |

≤0.6 |

2.5 ~ 4 |

|

SUS304 |

≤0.08 |

≤1 |

≤2 |

≤0.04 |

≤0.03 |

8 ~ 10.5 |

18 ~ 20 |

||

|

SUS420J2 |

0.26 ~ 0.40 |

≤1 |

≤1 |

≤0.04 |

≤0.03 |

0.6 |

12 ~ 14 |

||

|

SUS420F |

0.26 ~ 0.40 |

>0.15 |

≤1.25 |

≤0.06 |

≥0.15 |

0.6 |

12 ~ 14 |

Faahfaahinta Alaabta